As it seeks to address production issues with its current Ultium battery cells, General Motors may be considering something even more complex.

First spotted by Motor1, a recently filed GM patent application discusses battery cells with Lego-like shapes meant to accommodate cooling channels. Instead of building battery modules out of a solid mass of cells and installing a cooling plate underneath, as GM does with its current EVs, gaps between the cells would help improve cooling and extend battery life, the automaker claims in the application.

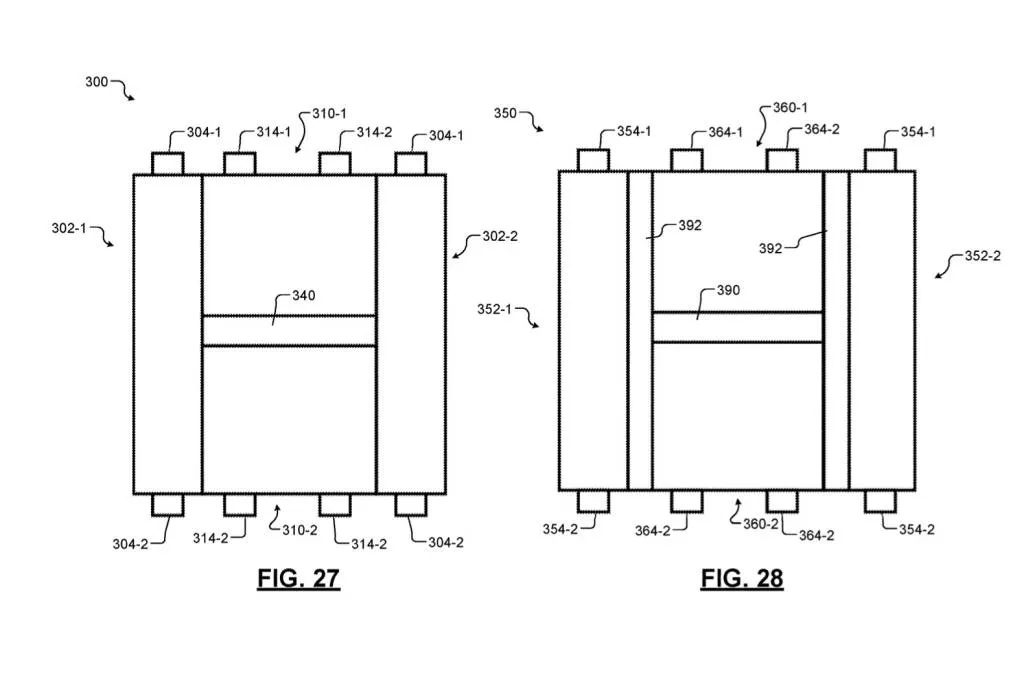

GM also claims a similar effect could be achieved with cells with a more conventional rectangular shape. In this version, cells of varying length and thickness would be arranged to create an H-shaped channel in the module to aid cooling.

General Motors Lego-like battery cell patent image

Either design would likely require GM to stick with roughly rectangular pouch cells, similar to what it’s currently using, rather than the cylindrical cells Lucid, Rivian, and Tesla claim have some thermal advantages, and that BMW is now adopting as well.

Automakers don’t always end up using the ideas they patent, so it’s unclear if this alternative form of battery cooling will appear in a production EV. GM has said that it’s flexible in its battery cells, but manufacturing nonuniform cells would likely add to the challenges GM is already experiencing in ramping up production of its Ultium EVs.

GM chose its current large-format pouch cells for being especially easy to make, but the automaker’s experience so far might suggest otherwise. According to a recent Bloomberg report, the automaker aims to build 200,000 to 300,000 EVs this year. That would be big improvement over the roughly 14,000 Ultium EVs sold in 2023, but still well short of original estimates, Bloomberg notes.

General Motors Lego-like battery cell patent image

The report claims GM “bypassed its own best practices” in order to start Ultium battery-pack production quickly. For example, it skipped the typical test of automated assembly line equipment, installing the equipment in its “Factory Zero” in Detroit without that testing. And it details battery-related fires at Factory Zero, including one that started after a forklift pierced a battery pack.

GM has also been plagued with software issues, which put deliveries of the Chevrolet Blazer EV on hold for months.

GM executives think the worst of these issues are now behind the company, and that it is crawling out of the “production hell” phase of the Ultium ramp, according to Bloomberg. But has GM gotten enough control over these issues to start moving on to new cell configurations?